Made in the UK by Leeds Welding Co Ltd so products are readily available.

LITE guard aluminium trench shields are in many cases structurally stronger than steel when it comes to the working loads of a trench collapse. With the development of improved aluminium products and clever engineering, the LITE guard shield was developed with higher strength aluminium than steel. Steel has a yield strength of 250mPa whereas the LITE guard aluminium shield has a yield strength higher than 300mPa.

LITE guard meets the safety requirements of the British/European standard BS. EN 13331.1 & 2, American standard OSHA Sub Part P and Australian/New Zealand standard AS 4744.1-200

LITE guard Trench Shields Strong in US Testing

Our LITE guard trench shields showed their strength under testing in the USA by our North American Manufacturer and Distributor National Trench Safety. When the trench shields were placed under an 80-tonne load of steel road plates the average deflection on the panels was only 65mm!

Our LITE guard trench shields showed their strength under testing in the USA by our North American Manufacturer and Distributor National Trench Safety. When the trench shields were placed under an 80-tonne load of steel road plates the average deflection on the panels was only 65mm!

With LITE guard you can DIG AND PLACE.

One major benefit of the LITE guard Trench Shoring system is that in most cases of up to 6.0m depth, the traditional method is to dig and push the boxes into the ground. This is slow and puts excessive force on the boxes and the back of the excavator buckets. With this method you are actually using the box to do the digging.

One major benefit of the LITE guard Trench Shoring system is that in most cases of up to 6.0m depth, the traditional method is to dig and push the boxes into the ground. This is slow and puts excessive force on the boxes and the back of the excavator buckets. With this method you are actually using the box to do the digging.

With LITE guard you can excavate no more than 150mm wider than the box to the bottom of the excavation. Pick up to 3 units and put them in place. The base of the excavation can be tidied up while the box is in place.

Installing via the dig and place system would reduce excavation time by more than 50%.

As the picture shows you could not do this with steel shields. With steel shields you would have no option but to dig and push and place one 3 tonne shield on top of the next one till you get to depth.

LITE guard can have built in cutting edges if you do have a need to dig and push.

Why UK contractors have to use the out of date method of DIG AND PUSH when installing trench shoring.

There are a couple of reasons:

- We have always done it this way.

- Due to the weight of steel trench boxes.

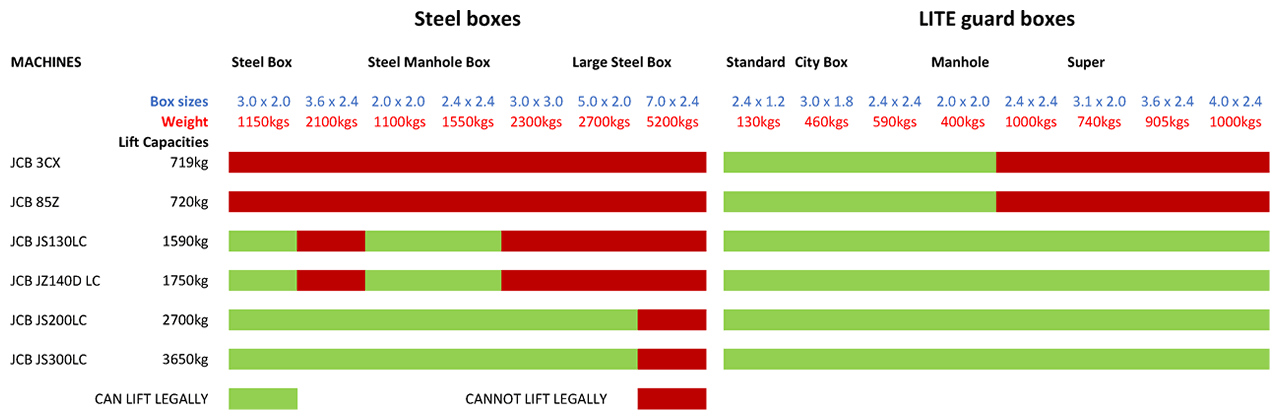

Most ground when excavated will stand long enough to place 2 or 3 trench shields into the excavated ground, if the excavator can legally lift them as one unit.

Being steel the total weight is too much for most machines on site to legally lift.

Using LITE guard trench shoring you can increase your production time by up to 50%. Excavate to the required depth, pick up the 1, 2 or 3 trench shields as one unit and place in the excavation. Then place some spoil either side of the shields or boxes to ensure they will not move.

Complete the job, either pipe laying or manhole installation and remove the shields.

The way to pick up 3 units: assemble 3 shields separately on the ground, pick one up and place on top of another and install the extension joiners, then pick up the two units and place on the 3rd shield and install the extension joiners. Now you have 3 units to place into the excavation.

Reverse the process to remove.

Using LITE guard trench shoring has the same speed benefits as using slide rail in place of sheet piles and frames.

LITE guard is a more efficient way to work.

That has been proven in the USA , Australia & New Zealand and now gaining traction in the UK.

See safe lifting capacity of a JCB back hoe and excavators lifting Steel Boxes and LITE guard boxes.